Accessories and optional features

Accessories to facilitate the loading, unloading, and transport of products to be treated.

Baskets

These baskets are made of stainless steel wire and can be fitted with a retractable side or even a vertically movable bottom to facilitate loading of your products. They are available in different sizes to suit the diameter of your autoclaves

Racks

Made from stainless steel, the racks are specifically designed to adapt to your products and guarantee optimum heat treatment. They can be compatible with robot mechanization, for seamless integration into your automated production lines.

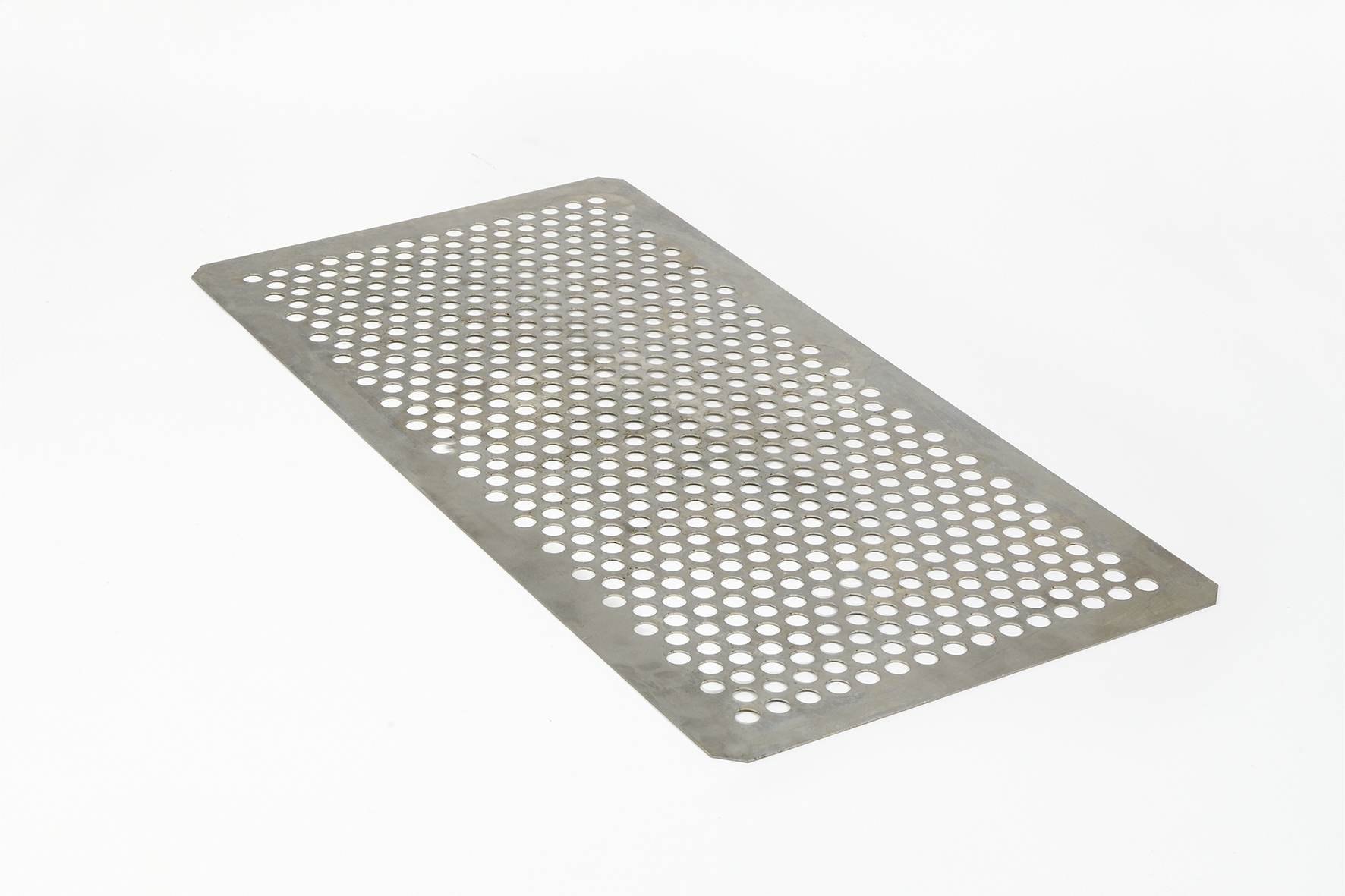

Interlayers

The spacers are available in different materials, thicknesses and sizes, to suit your baskets and products. The design is optimized to guarantee optimum heat transfer without marking the packaging.

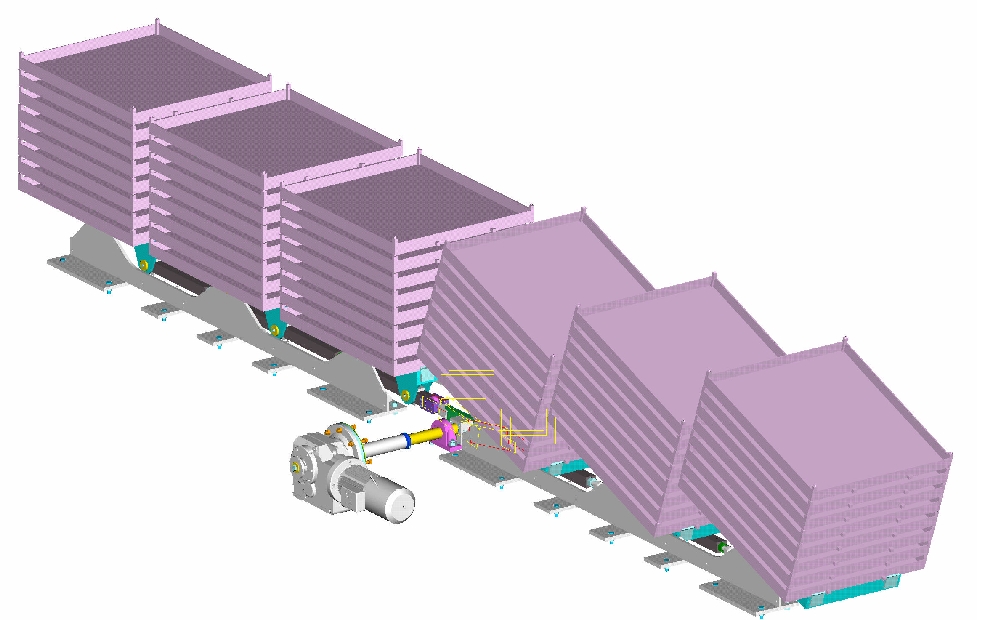

Caging and Uncaging

The basket loaders and unloaders are available in several models, designed to adapt to the different basket sizes used. Equipped with a lifting system, these devices can operate automatically or manually.

Trolleys

The trolleys are used to support baskets or stacks of racks. They are equipped with a wheel system for easy handling. They can be adapted to batch autoclaves or automated lines.

Components for the maintenance and improvement of autoclaves and continuous systems.

Spare parts

In addition to our machines, we offer a wide range of spare parts.

Quickly available, they guarantee the performance and longevity of your equipment.

Tools to facilitate the development of heat treatment processes

Temperature Probes (Thermocouple)

Temperature probes placed at the heart of the products and connected to our Trilogy software allow real-time monitoring of the core temperature. Our software also continuously calculates the sterilization or pasteurization value and can reduce cycle time when it is reached. It optimizes heat treatment according to the specific characteristics of each product, thus avoiding wasted time, overcooking and excess energy consumption.

PackSensor

The PackSensor puts an end to deformed packaging problems by measuring deformation and instantly adjusting backpressure to ensure optimal integrity. This intelligent sensor system is compatible with all types, sizes, and shapes of packaging, offering a flexible and reliable solution for your heat treatment needs.

Rocking System

The Rocking System allows for gentle product agitation, which optimizes heat transfer while ensuring consistent and rapid heat treatment. Suitable for all types of packaging, including the most fragile, this process reduces the risk of cold spots and shortens cycle times.