Industrial autoclaves:

our tailor-made sterilization and pasteurization solutions

Industrial autoclaves play an essential role in preserving products in the food and pharmaceutical industries. At Steritech, we design and manufacture solutions best suited to our customers’ needs in our workshop.

The different types of industrial autoclaves

Autoclave – Water Spray Process

The heat treatment in our Water Spray industrial autoclaves is achieved by spraying pressurized water onto the baskets filled with products.

The water is heated by direct steam injection into the autoclave or indirectly with an exchanger.

This process ensures uniform and efficient heat treatment during heating, temperature control, and cooling.

Autoclave – Water Spray Process

The heat treatment in our Water Spray autoclaves is achieved by spraying pressurized water onto the baskets filled with products.

The water is heated by direct steam injection into the autoclave or indirectly with an exchanger.

This process ensures uniform and efficient heat treatment during heating, temperature control, and cooling.

Autoclave – Air Steam Process

In Air Steam industrial autoclaves, steam is used to heat, cook, and sterilize products.

The fan ensures uniform heat mixing throughout the cycle. During cooling, pressurized water is sprayed onto the product rows.

The Air Steam process allows for energy-efficient, reliable, and rapid heat treatment.

Autoclave – Air Steam Process

In Air Steam autoclaves, steam is used to heat, cook, and sterilize products.

The fan ensures uniform heat mixing throughout the cycle. During cooling, pressurized water is sprayed onto the product rows.

The Air Steam process allows for energy-efficient, reliable, and rapid heat treatment.

Bi-process: air steam & water spray

The Bi-process combines both the steam-air process and the water spray process.

This approach is particularly effective for large-capacity industrial autoclaves.

By combining these two processes, the Bi-process optimizes heat treatment to the maximum, ensuring better heat penetration, more complete sterilization, and reduced cycle time.

Bi-process: air steam & water spray

The Bi-process combines both the steam-air process and the water spray process.

This approach is particularly effective for large-capacity autoclaves.

By combining these two processes, the Bi-process optimizes heat treatment to the maximum, ensuring better heat penetration, more complete sterilization, and reduced cycle time.

Immersion

The Immersion process autoclave is even more efficient than a traditional kettle or vertical autoclave!

This horizontal autoclave completely immerses products in water during sterilization and cooling. The water used during the cycle is recovered for recycling in subsequent cycles, thus avoiding waste.

Immersion

The Immersion process autoclave is even more efficient than a traditional kettle or vertical autoclave!

This horizontal autoclave completely immerses products in water during sterilization and cooling. The water used during the cycle is recovered for recycling in subsequent cycles, thus avoiding waste.

Goût’stave – the electric autoclave

Goût’stave, our small horizontal autoclave, is equipped with an electric heating element. Thanks to its small size and simplified operation, it’s perfectly suited to your R&D laboratories and allows you to conduct industrial tests.

It has a diameter of 800 mm and can hold one or two baskets.

Do you have an artisanal canning project ?

Goût’stave – the electric autoclave

Goût’stave, our small horizontal autoclave, is equipped with an electric heating element. Thanks to its small size and simplified operation, it’s perfectly suited to your R&D laboratories and allows you to conduct industrial tests.

It has a diameter of 800 mm and can hold one or two baskets.

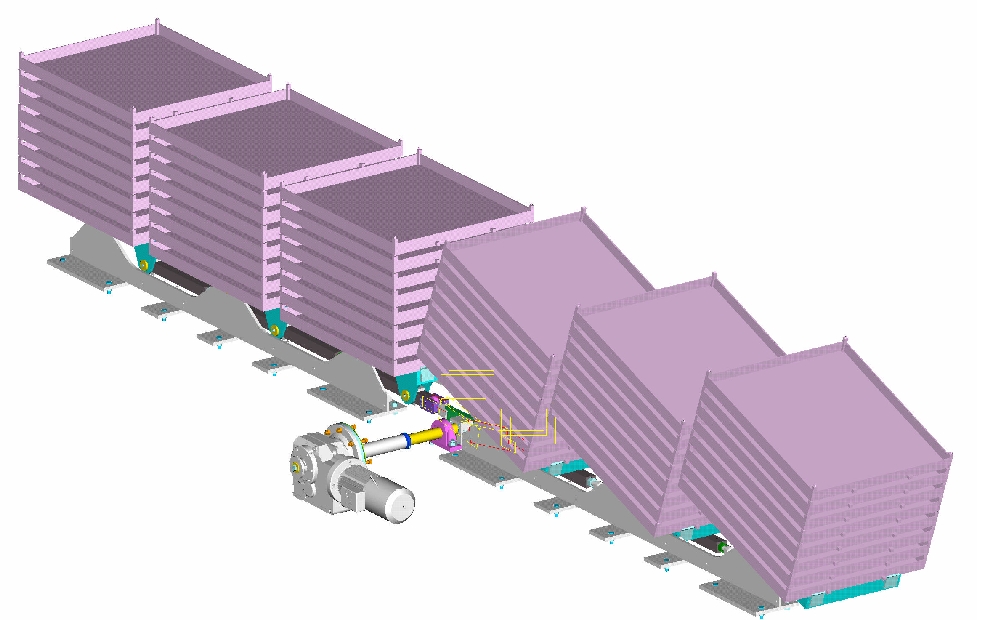

Why choose our industrial autoclaves?

Custom-made autoclaves!

Our range varies depending on your production rate and capacity.

We offer autoclaves:

- From 700 mm to 2000 mm diameter

- From 1 to 12 baskets (depending on the diameter)

- With one or two doors, either manually or automatically opening

Accessories (heat exchanger, pumps, nozzle arrays, etc.) are adapted to each solution combination.

Adaptability

Our autoclaves are suitable for all types of products and packaging. The integrity of flexible and fragile packaging is fully preserved.

Integrity of your products

The homogeneity of the heat treatment in our autoclaves allows the preservation of the organoleptic qualities of your products.

Speed and efficiency

Thanks to even temperature distribution, our autoclaves reduce cycle time by up to 25%.

Security and traceability

Manufactured and configured to measure, our autoclaves guarantee quality treatment and reinforce the food safety of your products.

Autonomy and security

Our autoclaves are equipped with a controller that controls the entire cycle. This makes using the autoclaves easier and safer for all operators.

Water and energy savings

Our autoclaves are designed to reduce energy consumption by up to 30%, or even more with the WatterloW system.