Maintenance and after-sales service

At Steritech, customer satisfaction is our top priority. Aware of the challenges involved in ensuring the ongoing performance of your equipment, we are committed to providing responsive, high-quality customer service.

Our aim: to keep your autoclaves running smoothly and your production processes running smoothly. Because we know that a production stoppage can lead to significant costs and lost time, we do everything in our power to minimize risks and maximize your peace of mind.

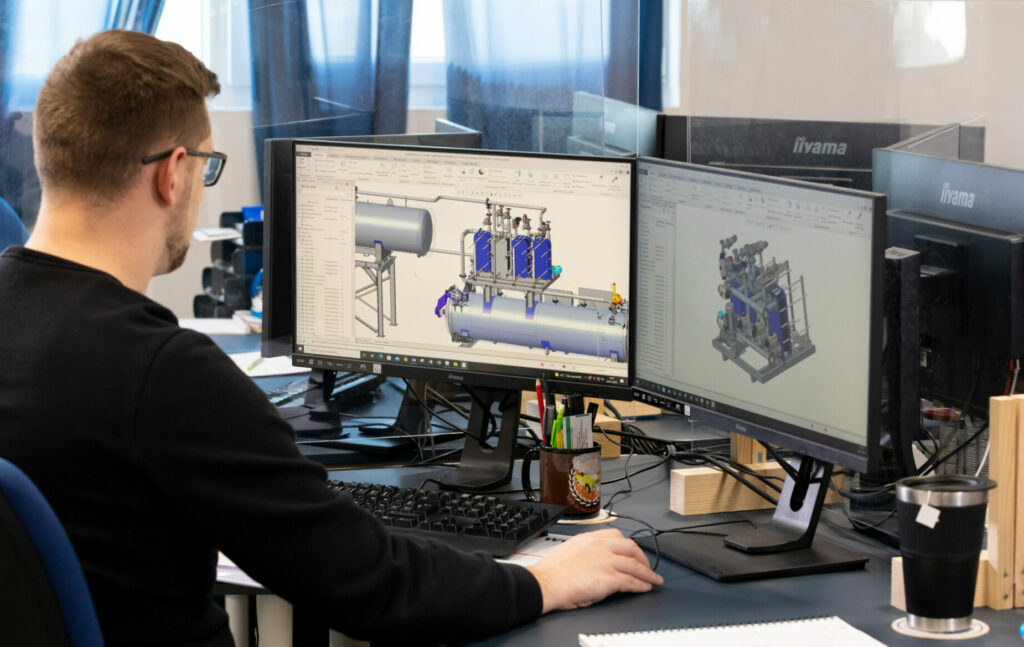

Machine design

We design and develop robust, reliable autoclaves with the aim of minimizing the risk of failure.

To guarantee simplified maintenance, our equipment incorporates standard parts that are readily available on the market, so you don’t have to depend on the shipment of specific spare parts.

Where necessary, we also supply component drawings, enabling you to carry out rapid troubleshooting with the help of your local partners, thus reducing downtime to a minimum.

Customized training in the use of our autoclaves

We offer tailor-made training courses, adapted to your needs, to guarantee complete control of your autoclaves. Our training courses include a session dedicated to hands-on practice .

They take place directly on your site, and enable you to train your teams in a number of key aspects such as: autoclave operation for optimum use, preventive maintenance to extend equipment life and reduce the risk of breakdowns, and the creation and optimization of sterilization schedules. These training courses are designed to empower your teams, while ensuring the continuous, reliable performance of your facilities.

After-sales support

Diagnosis and intervention

When we receive your call or request, our priority is to carry out a quick and accurate diagnosis to determine the best way to intervene and solve your problem.

Remote support:

Our autoclaves are equipped with remote connection technology via our TRILOGY solution, enabling us to work on your equipment in total security.

Thanks to this connection, our technicians can carry out instant diagnostics and propose troubleshooting solutions in real time. This approach drastically reduces downtime and eliminates travel costs, while ensuring rapid return to service of your installations.

On-site intervention:

If remote intervention isn’t enough, our teams can travel to your site to carry out corrective maintenance.

Thanks to the online audit, the technician arrives with all the necessary instructions and parts, guaranteeing fast, comprehensive support to restore your equipment to perfect working order.

International after-sales service

Our after-sales service is available worldwide, providing you with multilingual technical support wherever you are.

For all maintenance and service requests