Personalized support for your project

Steritech, your trusted partner for turnkey solutions

At Steritech, we understand that each sterilization and pasteurization project is unique and requires a tailored approach. That’s why we support you every step of the way, from the initial design to equipment commissioning and user training.

Thanks to our technical expertise and commitment to excellence, we ensure that every phase of your project runs smoothly, on time and within agreed budgets. Our dedicated team will do everything possible to realize your vision and ensure the success of your project.

Needs Analysis and Specifications for the Preliminary Study

- Understanding your specific objectives for your sterilization or pasteurization project.

- Conducting a preliminary study to define and size appropriate technical solutions.

- Assessing the constraints and opportunities of the existing site or new project.

- Testing is available in our laboratory to define and validate the appropriate heat treatment for your products.

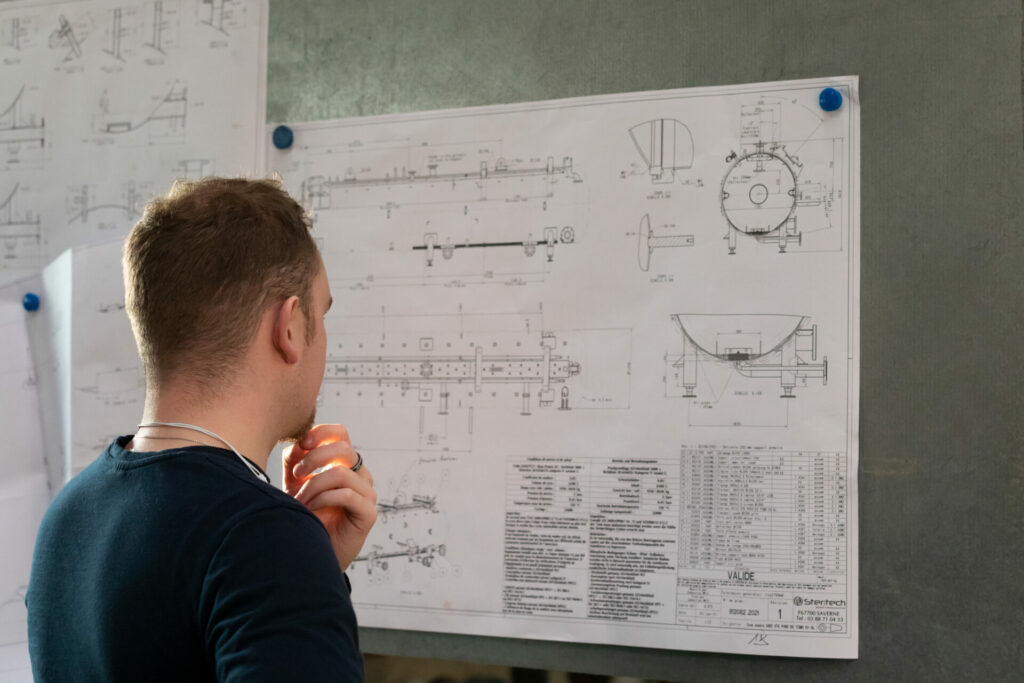

Custom Design and Planning

- Development of a customized technical solution, integrating performance, safety, and standard compliance requirements.

- Hydraulic, energy, mechanical, and electrical studies.

- Development of a detailed schedule, defining the deadlines and resources required for each stage of the project.

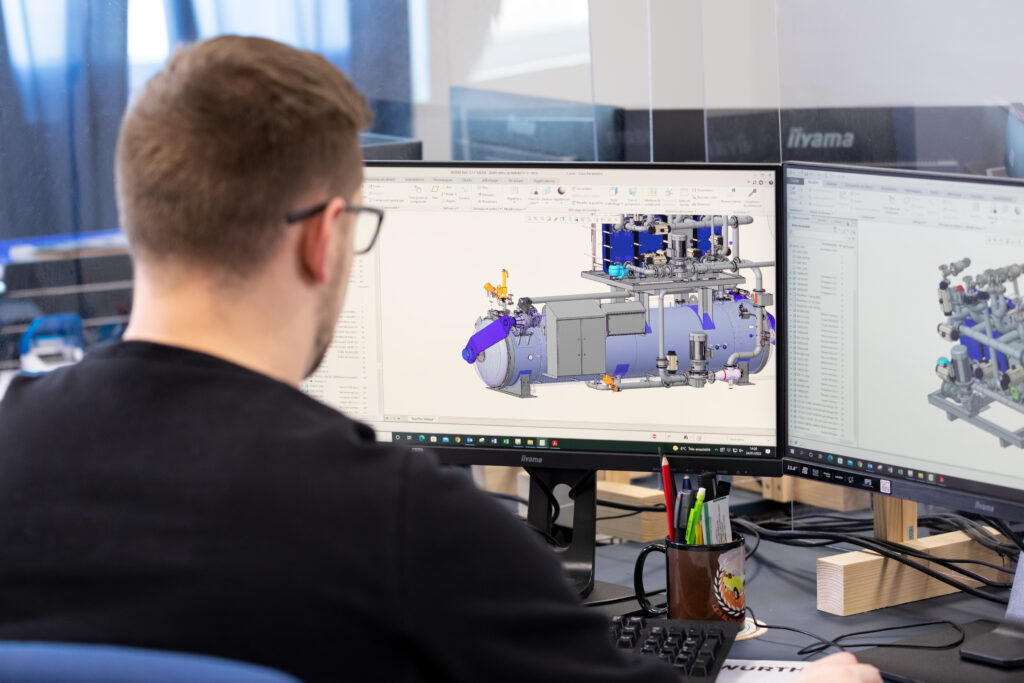

Engineering and modeling within our mechanical, electrical, and automation design offices.

- 3D design of equipment and systems in accordance with defined specifications.

- Virtual layout of your factory.

- Development of software specifications based on your needs and current factory operations.

Manufacturing in our workshop 🥨

Manufacture and assembly of custom equipment, guaranteeing quality and compliance with industrial standards.

Factory Acceptance Testing (FAT) available to validate equipment compliance.

Installation, Commissioning, and Training

- On-site equipment installation by our specialized assembly teams.

- Commissioning tests to verify the proper operation of sterilization or pasteurization systems.

- Training of operators, maintenance personnel, and managers to ensure effective handling of new equipment.

- Support available to validate product heat treatment (mapping, determination, and validation of scales).

Monitoring, Maintenance, After-Sales Service, and Retrofit

- Continuous monitoring of equipment performance after commissioning.

- Preventive and corrective maintenance services to ensure the durability and reliability of installations.

- Ongoing multilingual technical support from the After-Sales Service to meet customer needs and adjust systems in the event of changing requirements.

- Rapid diagnosis and intervention thanks to remote connectivity, enabling efficient problem identification and resolution.

- Retrofit: We can refurbish old equipment, regardless of brand, to give it a new lease of life, bring it up to standard, or boost its performance.

Do you have a sterilization or pasteurization project?

Contact us now to benefit from our support and find the solution perfectly suited to your needs !