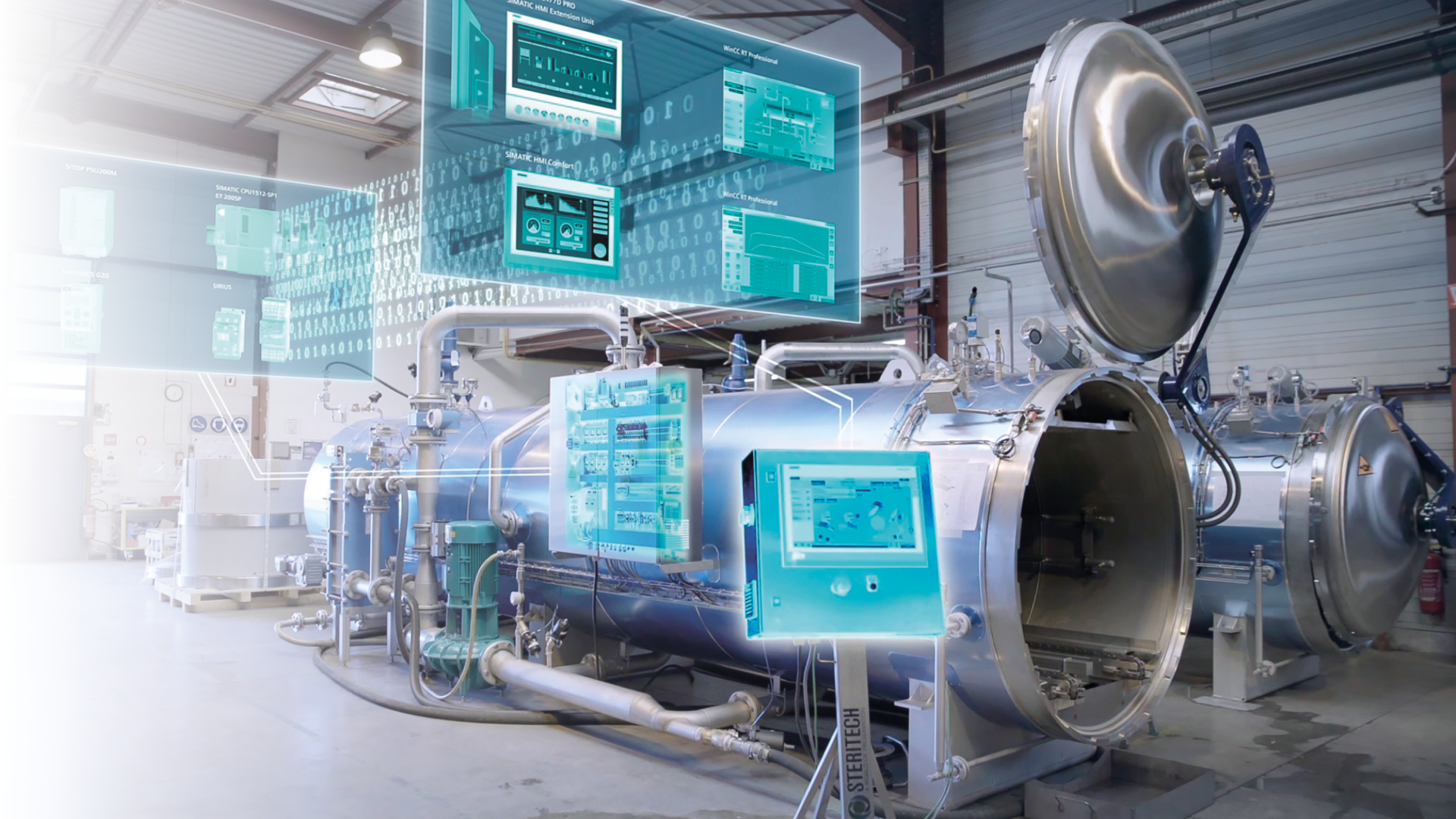

Retrofit your autoclaves: boost your equipment without changing it!

At Steritech, we integrate Retrofit into our eco-responsible approach to extend service life of your equipment while boosting performance and reducing their environmental impact.

Why choose Retrofit for your equipment?

📈 Enhanced performance

- Optimize the yields and productivity of your production lines

- Improve the energy performance of your equipment

💡 A gain for your operators and your products

- Increase safety and ergonomics by automating your production lines

- Simplify production supervision and management with fully automated systems interconnected with your ERP or MES system.

- Improve the quality, traceability and management of product and production data

🌳 An asset for your eco-responsible approach

- Reuse, modernize, extend: give new life to your existing equipment

- Reduce waste production: equipment is maintained and upgraded to produce better products for longer.

🚀 Stay at the forefront of innovation

- Adopt our advanced Trilogy 4.0 steering system

- Bring your equipment up to the latest industrial and safety standards

Are you interested in Retrofitting your equipment?

Steritech’s Retrofit service: a complete upgrade for your autoclaves

Retrofit at Steritech comprises a series of interventions that modernize your equipment without requiring complete replacement.

Our main operations

Component replacement and renewal

Our experts in maintenance and technical assembly replace defective parts with new ones, extending the life of your equipment and improving its reliability.

Compliance and safety

We analyze your current equipment to bring it into line with the latest safety standards. This includes replacing obsolete components and updating software, ensuring safe and efficient operation.

Intelligent automation of your production

We integrate automation solutions to simplify flows between each production entity, and in particular to optimize loading and unloading processes. This involves the addition of specialized hardware and the development of software capable of coordinating and synchronizing the various stages of the production line.

Intelligent Steering System: Trilogy 4.0

We install our advanced Trilogy 4.0 control system, which enhances the intelligence and automation of your equipment. This system has a significant impact on improving productivity, production capacity and energy performance, enabling your facilities to meet current and future requirements.

Would you like to find out more about our Retrofit service ?