Steritech Laboratory: personalized tests and tailor-made support

Steritech has a specially equipped testing laboratory to allow you to test and optimize sterilization or pasteurization processes before implementing a solution on an industrial scale.

Why carry out tests during the preliminary analysis phase of the project ?

✅ Process validation

Water spray or air/steam, continuous system or batch autoclave, which process is most suitable?

Conducting tests allows you to validate the sterilization or pasteurization parameters best suited to your products and thus ensure the process’ effectiveness before applying it to full production.

⚙ Development of new products

The trials also allow new formulations or new packaging to be tested to assess their resistance and behavior during sterilization or pasteurization processes.

📈Process Optimization

By carrying out tests, we can jointly identify the best operating conditions, reduce cycle times, improve energy efficiency, or even adapt parameters according to specific constraints.

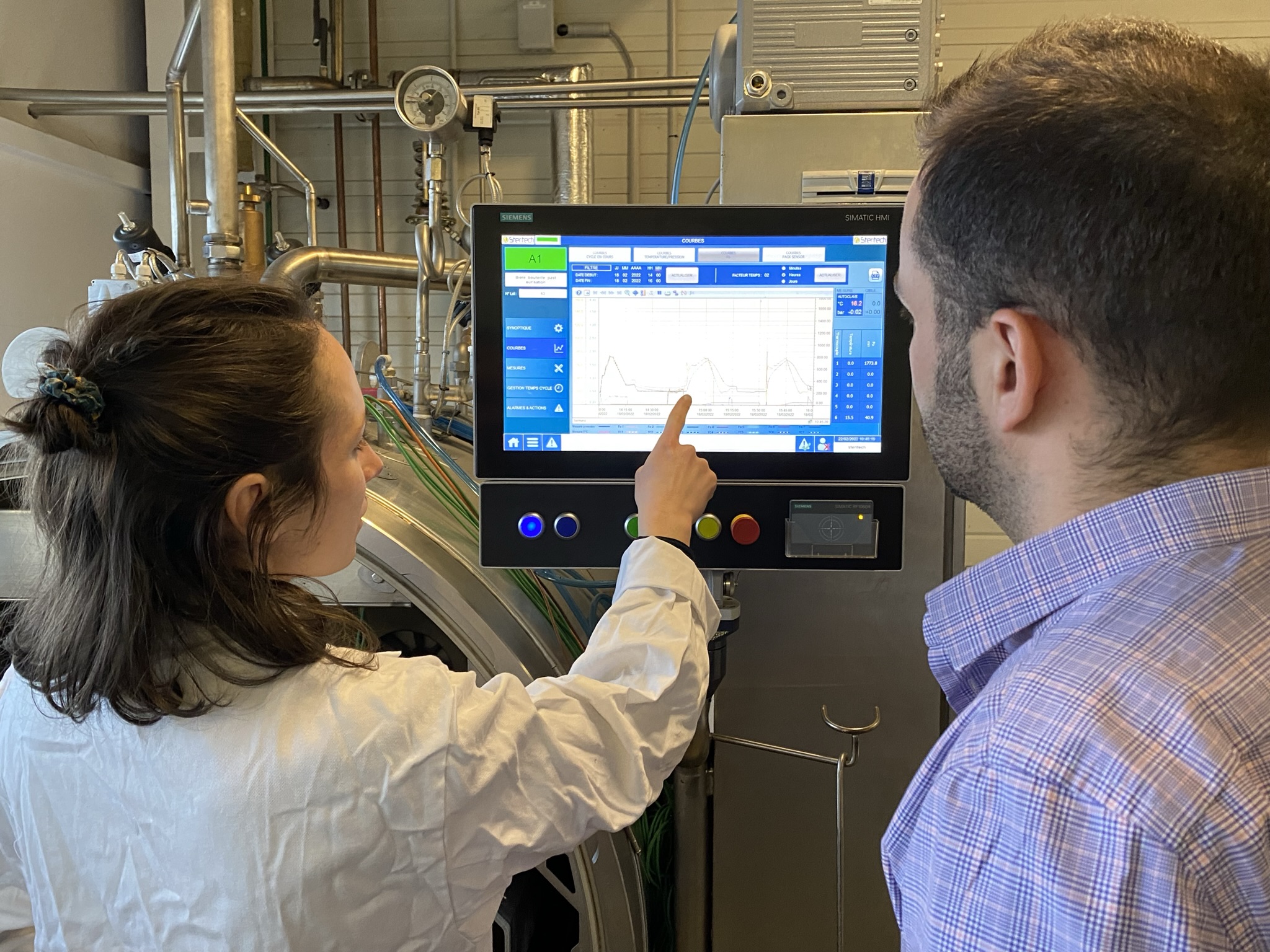

Support during testing and for the continuation of the project

Our food engineer will assist you throughout the testing process to determine the best solution for your needs. During the tests, we work closely with you to adjust parameters and optimize results. At the end of the tests, you will receive detailed reports, providing a clear overview of the results and recommendations for the next steps in your project.

Equipment available

Pilot autoclave to replicate all processes

Water spray, air/steam, dual-process, water immersion, processes with rotation or rocking system

Autoclave pilote pour reproduire les solutions continues

Serial Tower, (CHP/CHS) ou sans contre-pression (CMP)

Control software

Trilogy 4.0

Product temperature measurement equipment

wired probes connected to the autoclave and wireless probes

Pack Sensor:

Sensor that measures packaging deformation during the cycle and allows real-time control of the backpressure required to prevent deformation.

Energy consumption measuring equipment

Depending on the sterilized or pasteurized products

Other materials

Thermowell, cable glands, etc.

The + STERITECH

Software tailored to product development

The measurement equipment connected to the autoclave allows cycle times to be controlled based on product parameters. This allows for optimization of temperature and pressure curves during each phase of the cycle.

The variety of equipment and materials available allows the process to be adapted to ensure the microbiological safety of products, the preservation of the organoleptic qualities of products and the integrity of packaging.

If Alsace seems too far away, we can offer you the option of testing at your home or at our partner laboratories:

- CTCPA of Nantes

- Lycée agricole André Paillot

(Saint-Genis-Laval-69)

If traveling is a challenge for you

You can also send us your products. We’ll test them and then share photos and a full report with you.

Explore new possibilities and optimize your processes with the expertise

and testing capabilities offered by the Steritech laboratory.