Our solutions for continuous-flow heat treatment

If your challenge is to optimize or automate your heat treatment processes, discover our continuous solutions!

Continuous, modular solutions for high production capacities

Serial Tower

The most productive system on the market, expert in flexible and fragile packaging

Continuous Modular Pasteurizer (CMP)

The most modular, highly flexible pasteurization system

Continuous Hydrostatic Sterilizer (CHS)

The most adaptable sterilization system for your products and packaging

Continuous Hydrostatic Pasteurizer (CHP)

The pasteurization system best suited to your products and packaging

Continuous Modular Retort (CMR)

The modular autoclave designed for continuous flow heat treatment

The benefits of our continuous solutions

Tailor-made solutions for sterilizing or pasteurizing your products in a continuous flow

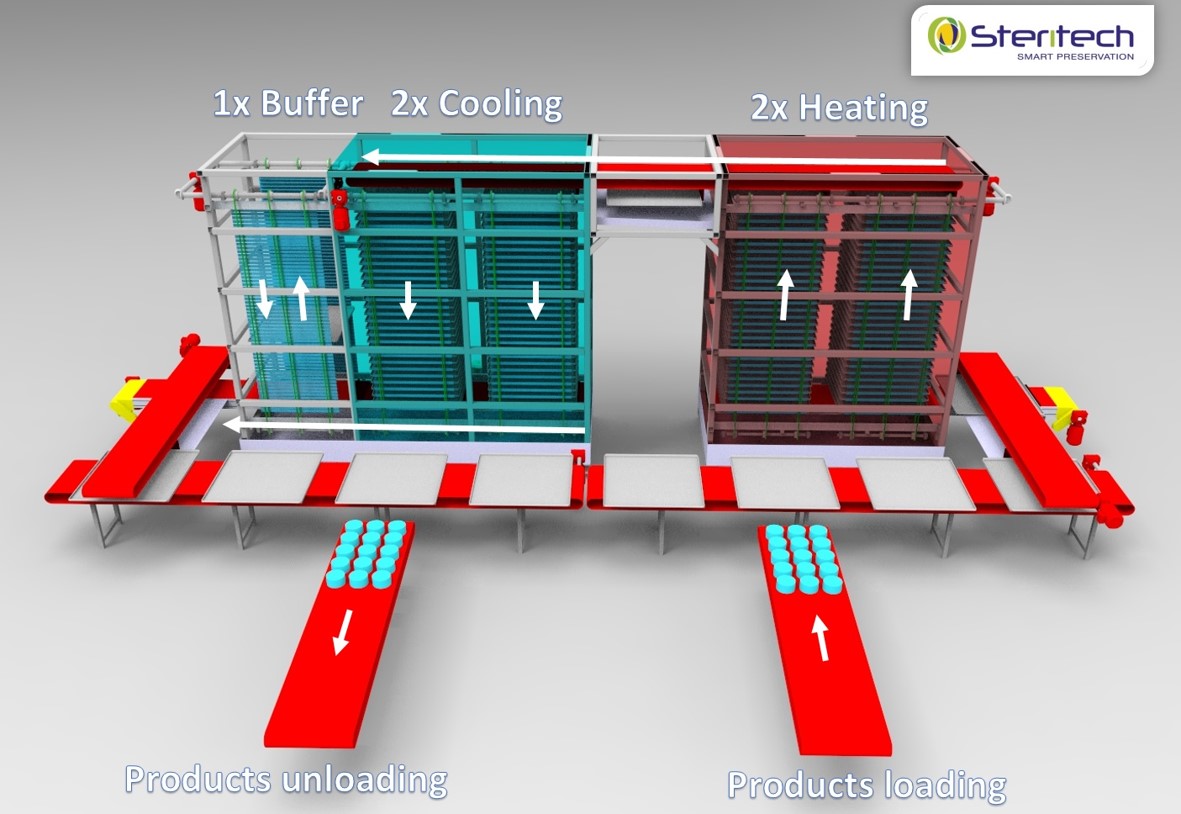

Serial Tower

The Serial Tower is the perfect solution for flexible and fragile packaging, which requires counter-pressure to preserve its integrity.

The Serial Tower is a continuous pasteurization-sterilization system in which your products are placed on plates. It consists of at least two towers, with adjustable counter-pressure of up to 2 bar per tower, one for heating, the other for cooling, through which the product-filled plates pass.

The Serial Tower can also be coupled with the Continuous Modular Pasteurizer (CMP), for even greater capacity and cost-effectiveness! CMP elements can be placed upstream of the Serial Tower to preheat products, or downstream to cool them without back pressure.

Technical specifications

- Stainless steel tanks with diameters of 2,000 or 2,500 mm and heights of 5,000 to 9,000 mm depending on product cycle rates

- Plates with useful dimensions of 1,200 x 1,200 mm or 1,600 x 1,200 mm

Continuous Modular Pasteurizer (CMP)

The Continuous Modular Pasteurizer (CMP) enables you to pasteurize your mass production in a continuous and flexible way by placing your packaged products on plates. It operates without back pressure and can be made up of 4 modular zones:

– the 1st for pasteurizing your products up to 90 – 95°C

– the 2nd to pre-cool your products to a core temperature of 30 – 40°C

– the 3rd to cool them to a temperature of 4°C

– the 4th for automatic storage of your products in the event of temporary stoppage of your production line, thus preventing your products from remaining in the hot zone or heating up after leaving at 4°C.

Highly modular, the CMP is suitable for customized heat treatment and easy variation of recipes and cycle times.

As well as being totally modular, the CMP is highly flexible:

– precise temperature adjustment by zone (hot and cold sections) ;

– adapted to your packaging shapes and sizes;

– cycle time adjustment ;

– possibility of “by-passing” different elevators ;

– elevator pitch adjustment (every second or third pitch) ;

The CMP can also be coupled with the Serial Tower for preheating or further core cooling.

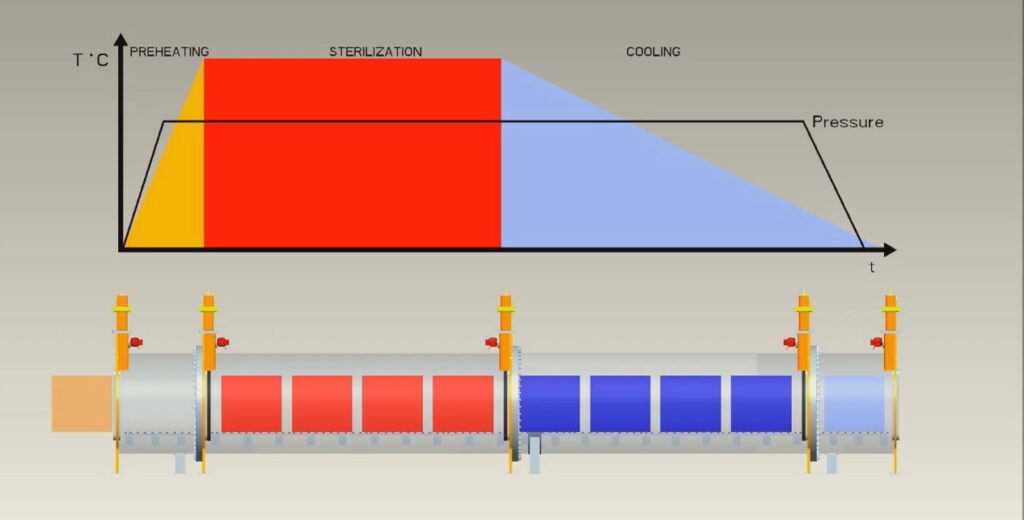

Continuous Hydrostatic Sterilizer (CHS) – Pasteurizer (CHP)

If your challenge is to manage the production of a wide variety of packaged products at high speed, the Continuous Hydrostatic Pasteurizer (CHP) or Continuous Hydrostatic Sterilizer (CHS) is THE solution for you!

The CHP and CHS are made up of various zones dedicated respectively to temperature rise, heat treatment and product cooling.

Each zone is subdivided into several columns, within which specific exposure times, temperatures and pressures can be set independently.

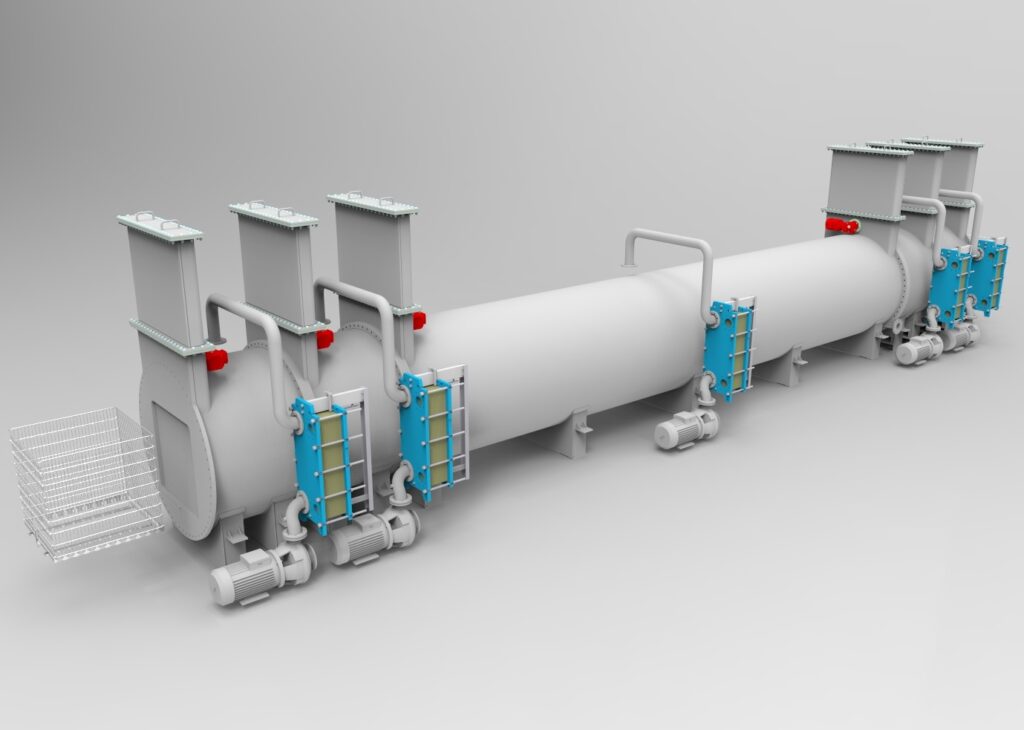

Continuous Modular Retort (CMR)

The Continuous Modular Retort (CMR) is an innovative industrial autoclave designed for continuous thermal processing. This technology allows for the continuous entry and exit of baskets or stacks of racks, ensuring smooth and efficient production. Designed to be installed in low-height premises, it easily adapts to different environments. It is compatible with baskets, stacks of trays, and their loading systems.

Like our continuous hydrostatic system (CHP/CHS), the CMR is based on a modular process: each module isolates a specific stage of the sterilization or pasteurization cycle. Thanks to this architecture, it is possible to precisely control the temperature and pressure in each zone, ensuring the reliability and quality of product treatment.

Why choose our continuous solutions?

At Steritech, we develop, manufacture and install flexible, turnkey, tailor-made solutions for continuous sterilization and pasteurization of your products all over the world.

This enables you to achieve high production capacities while guaranteeing the safety of your products and meeting your technical and technological constraints.

Design a complete turnkey solution, including peripheral equipment, adapted to your specific products and constraints

Respect the FIFO principle (1st product in, 1st product out)

Save time in production and accelerate your output, with up to 45% less cycle time!

Improve heat treatment consistency for all your products

Automate your production: an integrated conveyor system ensures automatic flow from your production line to your packaging shop.

Ensure the preservation and quality of your products in terms of taste and smell

Reduce floor space by up to 80% for equivalent capacity

Saves water, energy up to 15% and steam up to 23% compared to an equivalent autoclave line

Ensure complete and optimal traceability of your products

Benefit from a CE, TUV, SVTI, ASME-certified industrial solution